Correct installation of air compressor is very important, incorrect installation will lead to the normal operation of air compressor, will seriously affect the life of air compressor, and will bring additional maintenance and maintenance costs.

I. Location of Air Compressor Room

_1. Air compressor room should be as cool, clean and well ventilated as possible, with ambient temperature between 0-40 C.

2. The air compressor room should have lifting equipment. If there is no standard lifting equipment such as traveling crane, at least temporary lifting equipment such as forklift truck and gantry frame, as well as the installation location or access channel of these equipment are also needed.

_3. Air compressors should be absolutely avoided to be installed outdoors, so as to avoid rain and sunshine and excessive dust entering the unit.

4. The air compressor should absolutely avoid installing in the narrow space without ventilation, so as to avoid the adverse conditions such as high exhaust temperature of the unit.

5. Air compressors should be absolutely avoided to be installed in places with more dust in the environment, especially near sandblasting equipment, in order to avoid excessive wear and tear of the unit.

6. The air compressor should absolutely avoid installing in the air where there are combustible gases, corrosive gases and more water vapor, so as to avoid possible explosion or internal corrosion.

II. Layout of Air Compressor Room and Placement of Air Compressor

1. Gas storage tanks should be installed behind the air compressor. The volume of gas storage tanks should be more than 20% of the exhaust volume per minute of the air compressor, and personnel should be arranged to drain regularly.

2. If there is a dryer in the air compressor room, the storage tank must be installed before the dryer so that the compressed air discharged by the air compressor can be properly buffered and cooled before entering the dryer. The dryer needs a bypass valve for future maintenance.

3. Air compressors should be placed directly on the level cement floor which can bear the weight of air compressors.

4. No special requirements, air compressor does not need cushion or shock absorber.

5. The distance between the air compressor and the surrounding wall or other equipment should be more than 1.5m in order to facilitate the inspection and maintenance of the air compressor.

3. Pipeline connection of air compressor

1. Air compressor exhaust pipe connection:

A. In order to avoid condensate backflow, the exhaust pipe of the air compressor should be connected to the main pipe from above. If there are many air compressors, this connection is more needed. Please refer to Figure 2.

B. The diameter of the exhaust pipe of an air compressor shall be equal to or greater than the diameter of the exhaust port of the unit.

C. Isolation ball valves should be installed between the exhaust pipe and the compressor, but check valves are generally not required.

2. Water-cooled air compressor cooling water pipe connection:

A. Air compressor cooling water intake pipes must be equipped with 'Y' shaped or other forms of high efficiency water filters with a filtration density of about 40 mesh.

B. Isolation ball valves must be installed between cooling water inlet and outlet pipes and cooling water main pipes, and winter discharge valves should be installed on pipes between ball valves and air compressors.

C. It is better to install water pressure gauge and water temperature gauge on the cooling water inlet and outlet pipes.

4. Cooling Water of Water-cooled Air Compressor

1. The water pressure of cooling water is generally controlled between 0.3 and 0.5 MPa, and the pressure difference between inlet and outlet water should be above 0.15 Mpa.

2. The temperature of cooling water should be controlled below 35 C. In general, cooling towers should be installed in the cooling water system.

3. The reference flow rate of cooling water is as follows. It can be adjusted and selected according to the power of the unit. If more accurate flow rate is needed, please refer to the operating instruction of the air compressor.

Under 100 HP: 15 m3/h; 100-200 HP: 20 m3/h;

200-300 HP: 25 m3/h; over 300 HP: 30 m3/h;

4. Water quality requirements:

A. pH: 6.8 < pH < 8

B. Total dissolved solids: < 450 mg/l

C. Total hardness (expressed in CaCO3): <300 mg/l

D. Suspended solids: < 50 mg/l

E. Chloride (Cl-): < 150 mg/l

5. Customer's water quality should be checked regularly. If the water quality does not meet the above requirements, the cooling water must be treated with professional water treatment methods until the water quality reaches the standard.

6. Because the water quality of deep well water is very hard, the direct use of deep well water should be avoided.

Note: In case the cooler scales in future use and can not be removed by acid cleaning, professional water treatment methods should be used, and chemicals that do not corrode metals should be used to clean the cooler.

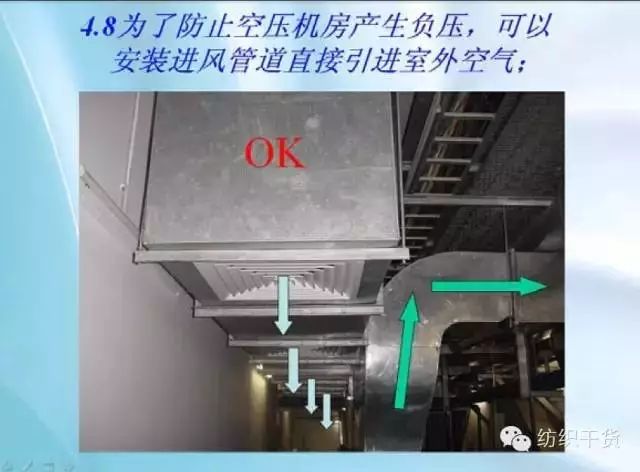

V. Ventilation of Air Compressors

The operation of air compressor will produce a lot of heat. Usually, these heat needs to be discharged outdoors to avoid the excessive temperature of air compressor room, which exceeds the normal industrial environment temperature, i.e. the maximum temperature is not higher than 40 C. There are several ways to maintain the normal environmental temperature of air compressor room:

1. If the power of the unit is not large and the room is spacious, it may be considered to install an exhaust fan directly at the height of the room wall and directly exhaust the hot air from the room to the outdoor. The exhaust volume of the exhaust fan may refer to the following formula a) or B.

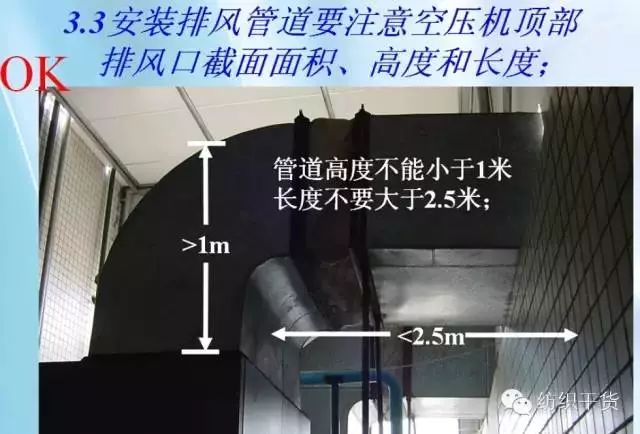

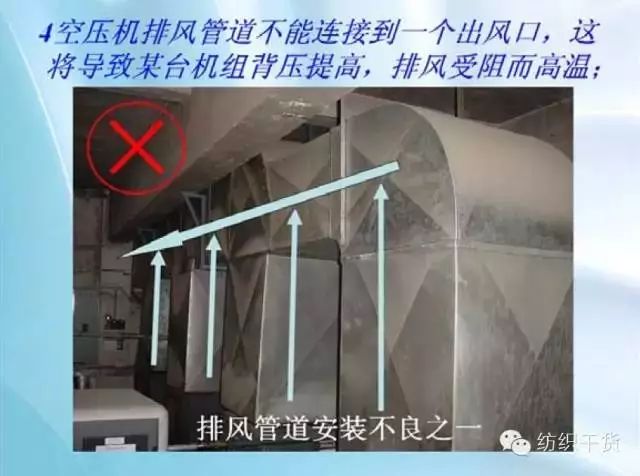

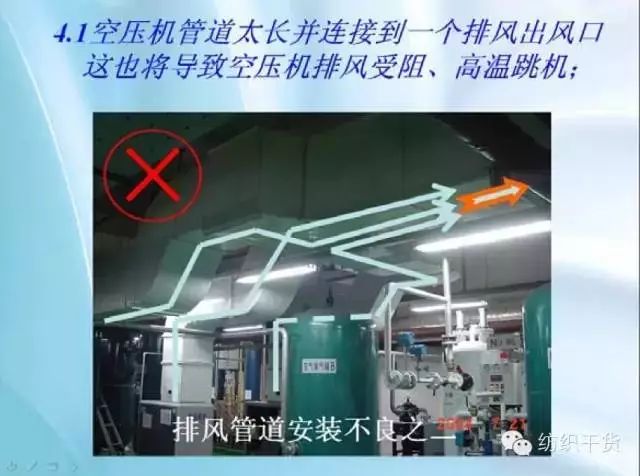

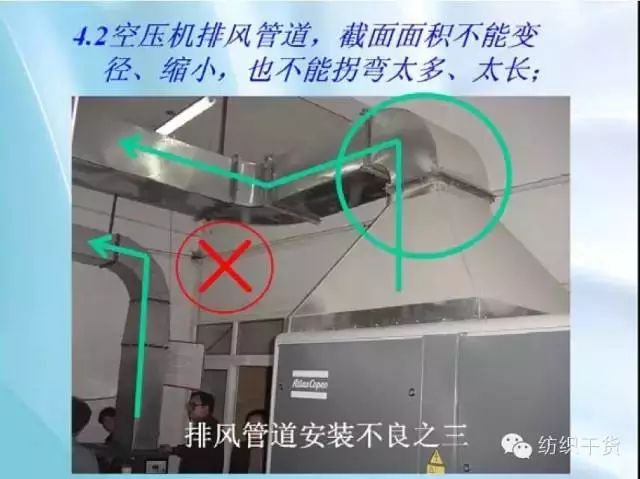

2. If the power of the unit is large, the hot air can be induced outdoors by the air duct. The cross-section size of the air duct should be the same as that of the air compressor itself, and the whole air duct can not shrink from beginning to end, the air duct can not turn too fast, and the appropriate radian should be ensured.

3. If the length of the air duct exceeds 5 m, or the temperature of the air compressor room after the air duct is still too high, it is necessary to install an exhaust fan at the outlet of the air duct to strengthen the ventilation of the air compressor. The exhaust volume of the selected fan can be calculated by the following formula a) or b):

A) Ventilation rate of air-cooled air compressor: Qv = 0.92 N/dT m3/s

B) Ventilation of water-cooled air compressor: Qv = 0.1N/dT m3/s

Note: In the two formulas above:

Qv = necessary ventilation m3/s

N = Axis power of compressor in KW unit

DT = air compressor room temperature rise, generally take 8 C

6. Installation of Main Circuit Cable of Air Compressor

1. The cable configuration of low-voltage power supply refers to the instructions for use.

2. Standard fuse wires and isolation air switches must be installed on the line of low voltage power supply. Fuse wires and isolation switches should be installed near the air compressor and easy to access and control.

3. High-voltage cables should be designed and installed according to national standards by qualified design units.

4. High-voltage motor housing must be grounded by pulling a separate grounding wire.

5. When installing cable, there should not be too much stress to avoid short circuit caused by cable loosening in the future.

6. Cables should not be in contact with metal fast ports in order to avoid short-circuit caused by cable breakage in the future.

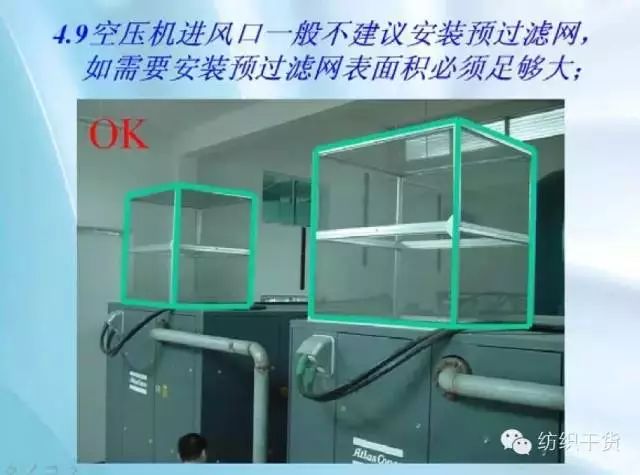

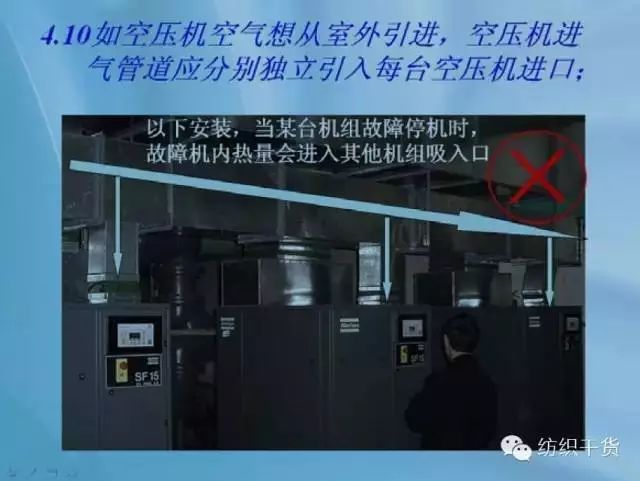

7. Reference for Ventilation Pipeline Installation