Product characteristics:

1. Save heart and money: no extra tedious pipeline installation, or even no bypass configuration, link reduction, really save heart, trouble and money.

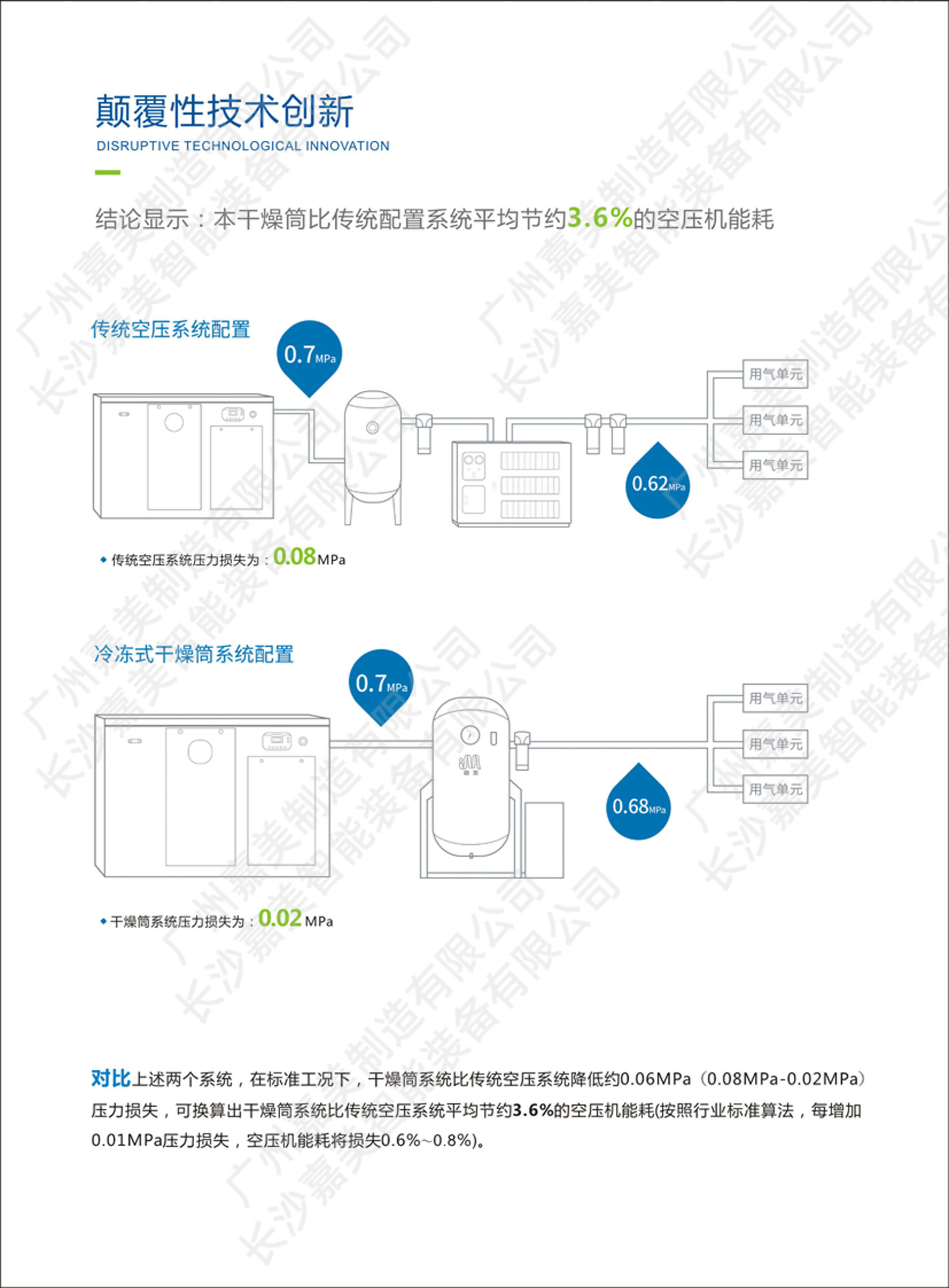

2. Ultra-low pressure loss: cold dryer, gas storage tank, three-stage filter dislocation in one, completely change the flow direction of compressed air, indirectly save the energy consumption of air compressor.

3. Integration of three certificates: the process of forensics is simplified, and users are more convenient to manage.

4. Stable operation: Patented structure design, fewer solder joints, smooth compressed gas flow, fearless pulse of key components, more stable operation.

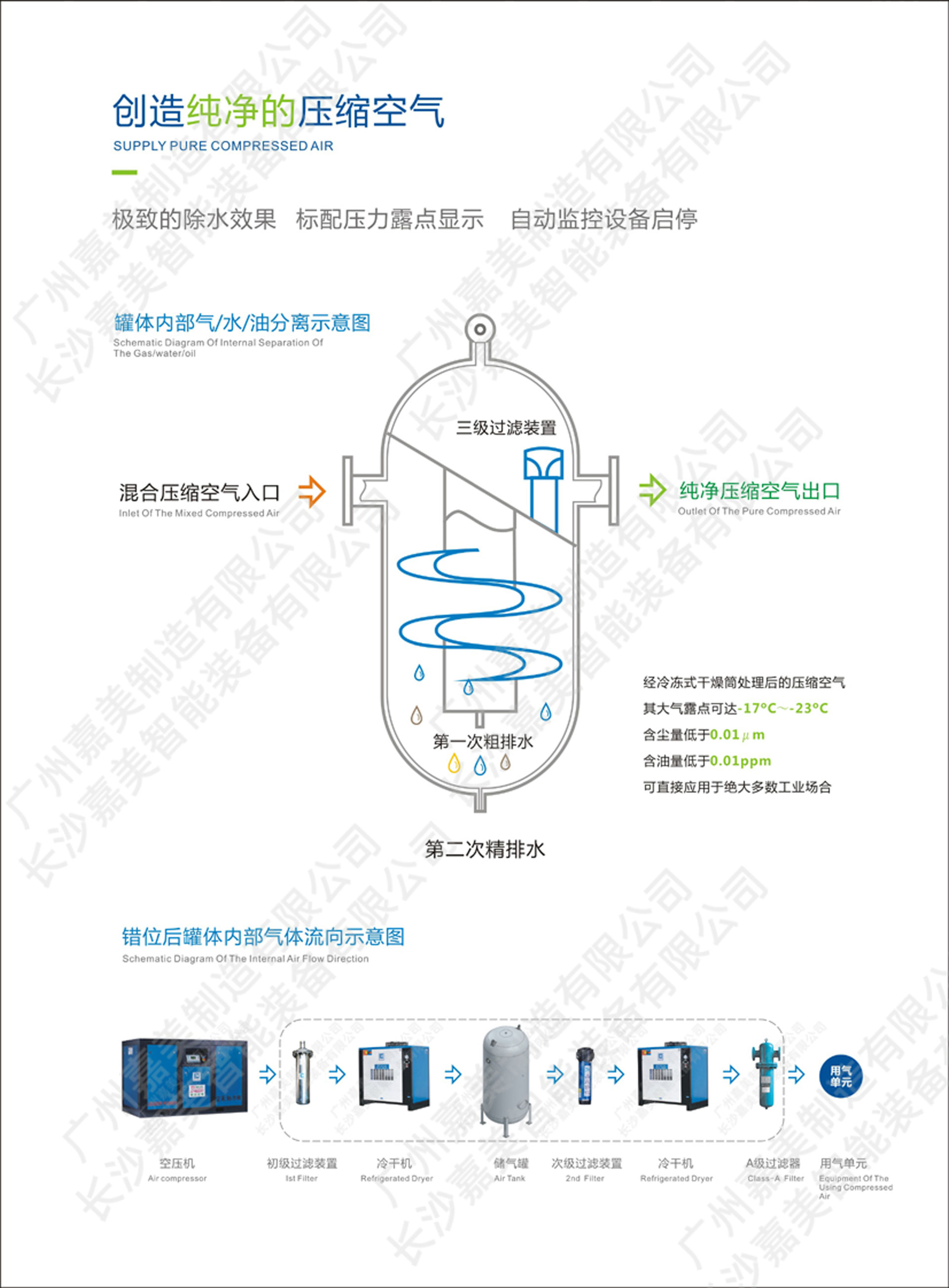

5. Extreme dewatering: Excellent dewatering effect, real-time pressure dew point display, and automatic monitoring of compressor intelligent start and stop.

6. Environmental protection and energy saving: Green R410A refrigerant is used to respond to international environmental protection requirements.

7. Separation optional: Unique concept of separation, when the site conditions are bad, the refrigeration system can be divided into suitable places to the environment.

8. Space actuarial: three-in-one highly integrated, reducing multiple links and occupying less space.

9. Fast transfer: The whole system can transfer quickly according to user's needs at any time.

10. Easy maintenance: modular design, core extraction, more convenient service, commitment to two-year warranty, five-year extension optional.

Principle diagram of freeze drying drum system

The refrigerated drying drum is a new high-end post-processing system of compressed air introduced from Taiwan parent company. It integrates the compressed air purification system of the back end of the air compressor with the gas storage tank, and changes its internal gas flow direction: air compressor primary filter device cold dryer storage tank secondary filter device cold dryer A filter gas unit, so as to integrate the compressed air purification system of the back end of the air compressor with the gas storage tank. The pressure loss of the system is reduced by more than 70%. The dew point of compressed air treated by freeze drying drum can reach - 17 C to - 23 C, the dust content is less than 0.01 um, and the oil content is less than 0.01 ppm. It can be directly applied to most industrial occasions. If combined with adsorption dryer, a combined drying cylinder can be formed.