Class C Main Line Filter

Suitable for filtering large amount of liquid and 3 micron size condensate, reaching the maximum residual oil content of 5 ppm w/w.

Level 1 - Double Stainless Steel Screen Mesh with Collision Effect for Primary Mechanical Separation

Level 2 - Multilayer Fiber Medium with Gravity Effect, Electrostatic Effect and Diffusion Effect to Filter Fine Liquid Particles

T-Class Air Pipeline Filter

It is suitable for filtering liquid water, oil and dust, and can filter solid particles as small as 1 micron, reaching the maximum residual oil content of 0.5 ppm w/w.

Stainless steel sieve mesh, with interception effect and inertia effect, is used for mechanical separation.

Level 2 - Multilayer Fiber Medium with Gravity Effect, Electrostatic Effect and Diffusion Effect to Filter Fine Solid Particles

Class A High Efficiency Degreasing Filter

It is suitable for coalescing fine water vapor and oil mist, and can filter solid particles as small as 0.01 micron, reaching the maximum residual oil content of 0.01 ppm w/w.

Stainless steel sieve mesh with interception effect and inertia effect for mechanical separation

Level 2 - Multilayer Fiber Medium with Gravity Effect, Electrostatic Effect and Diffusion Effect to Filter Fine Liquid Particles

AA Super High Efficiency Degreasing Filter

Downstream of freeze dryer, it can filter liquid and solid particles as small as 0.01m. The minimum residual oil content is only 0.001ppm. It is important to install a class A high efficiency oil removal filter upstream to protect it.

H Activated Carbon Oil Mist Filter

Most of them are used to purify food, medicine and breathing gases. They can filter oil mist and hydrocarbons as small as 0.01 um. The minimum residual oil content is only 0.003 ppm. It is important to install a super high efficiency oil removal filter upstream to protect it.

Introduction to the Advantages and Characteristics of Jiamei Precision Filter

1. The air handling capacity and product specifications of Jiamei filter are various and complete, and the inventory is sufficient, which can meet the various needs of users instantly.

The whole series of products are strictly and comprehensively inspected by the special machine for full-function pressure and leak test to ensure stable quality.

3. The pressure drop of Camry filter is small (<0.01 MPa).

4. The differential pressure indicator takes into account the automatic drainage device, so that users can grasp the best compressed air quality at any time, save the trouble of personnel maintenance, and work more smoothly and smoothly.

5 High efficiency dedusting and deoiling function can remove 99.9999% liquid water in compressed air, and filter to 0.01 micron cleanliness and 0.001 ppm minimum residual oil content.

The material of filter element is imported from Taiwan Matrix of our company. The quality is reliable and the service life can reach 8000 hours.

7. Easy replacement of filter element

The special lock-in filter element design is convenient for maintenance and replacement, and provides the strongest stability, avoiding loosening due to vibration in use; the filter element can load up to 96% of the air.

8 shell design is exquisite and easy to install and maintain.

Filtration space is added to maximize filtration efficiency and reduce pressure drop. The inner and outer surfaces are treated with corrosion resistant coating to ensure no rust.

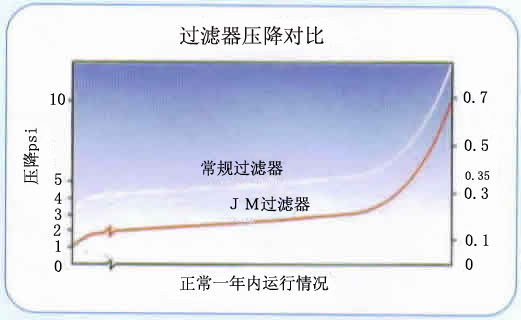

The working pressure drop is one of the important parameters to measure the performance of the filter.

The working pressure drop of the filter produced by our company is 50% of that of the conventional filter.

Compared with the traditional filter, the filter material produced by our company does not absorb liquids to ensure that the void can accommodate the largest amount of dust, while the water mist is condensed on the sponge which can be carried twice, and discharged through the drainage valve after flowing into the filter cup.